ProGrind Grinders & Chippers

About ProGrind

From the entry level ProGrind™ 1500 to the top-of-the-line ProGrind™ 5200, wood-waste processing systems are designed with innovative features to give you high production output, no matter how big or small the job. And with Precision, you’ll not only get top-performance equipment, but industry-leading service as well.

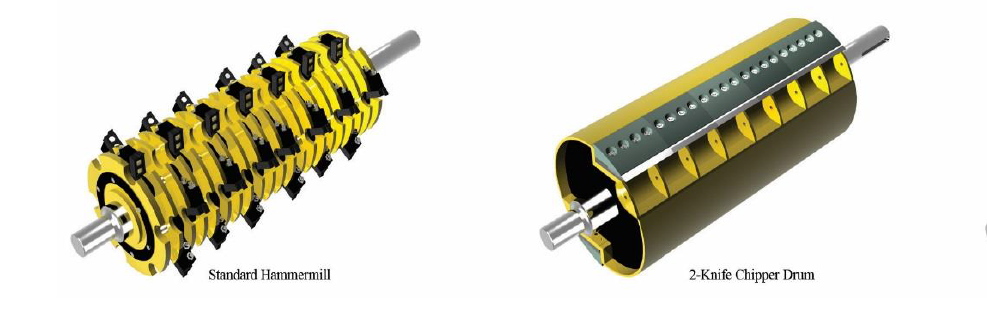

Combirotor

ProGrind has an exchangeable rotor design to quickly change rotor for CHIPPING or GRINDING. Within 4-6 hours a ProGrind can be changed from a grinder into chipper for the production of biofuel chips.

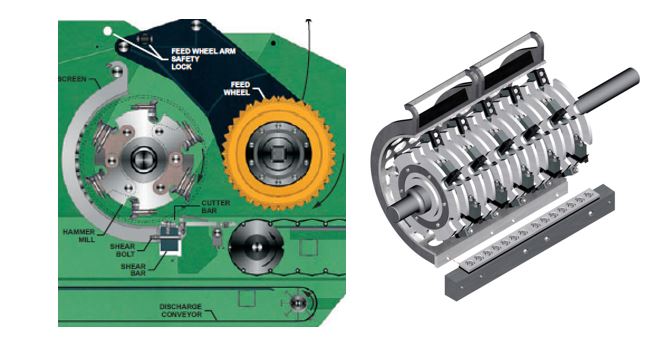

Dual Shear Protection

ProGrind provides Dual shear protection for hammermill. In case foreign material like metal hits the hammermill then a shear bolt protection will release the screens and a shear bar will make the cutter bar drop down, both immediately creating space for the foreign material to go out and to minimize damage to hammermill.

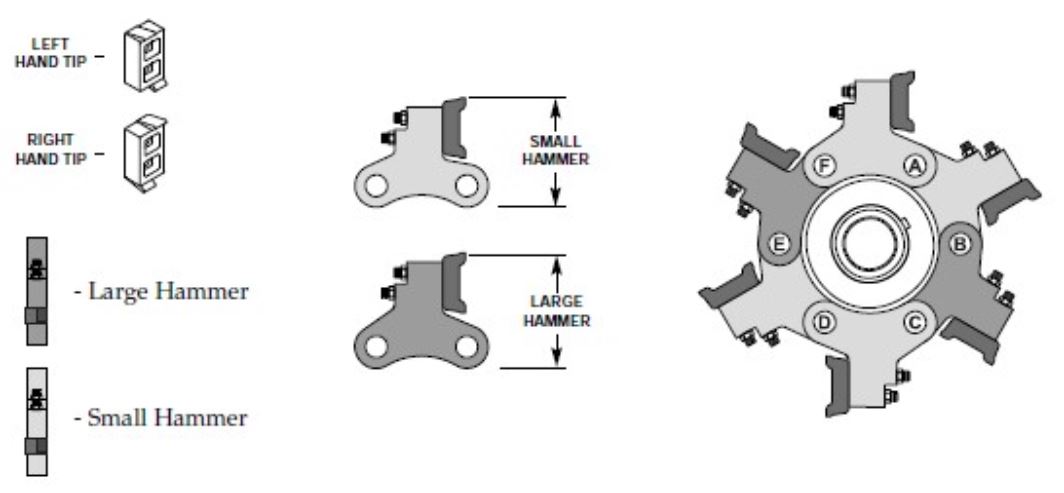

Hammermill design

Hammermill design: ProGrind has two-bolt notched fixed hammers with double cut design. Fixed hammers are supported by hammer bodies, which create high impact force and make the rods more protected against wear. Supported by a double-cut design, the ProGrind Hammermill virtually eliminates the frequent jamming known for by more conventional type grinders

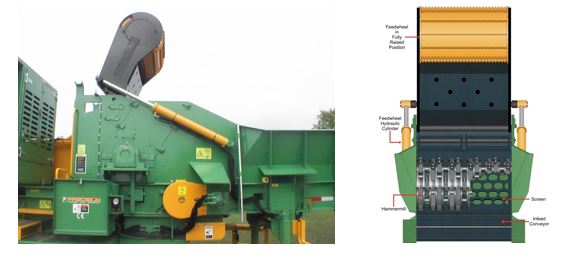

Feedwheel design

Feed wheel design: The large diameter feed wheel can be fully raised to ensure easy acces of hammermill for maintenance.

Infeed wheel can climb vertically without limitation to ensure easy intake of voluminous material.

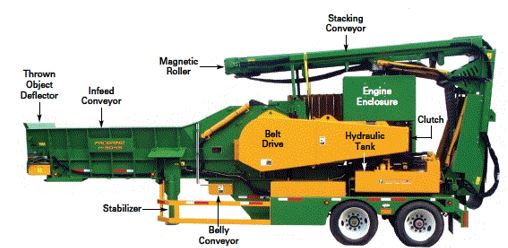

Large dsicharge conveyor

Large foldable Stacking Conveyor has dimension of 48” [1.22m] wide x 25’-6” [7.77m] long, and includes a magnet for metal separation.